Forum Replies Created

-

AuthorPosts

-

forestmanParticipant

forestmanParticipantUpdate, swap has taken quite a few days longer than I had expected, then again looking back my timeline was really optimistic, however, 5 days on top of the original timeline and I’m pretty much done.

So, body is swapped, cab is mounted, timing belt water pump service complete, driveshafts are in, shifter cable and steering linkage hooked up electrical is all hooked up, coilovers are in. Started the truck and then I realized I put in the half burnt out power steering pump from the 02, but it worked fine, long enough to get the engine up to temp and check for leaks (there were none). Engine runs like a dream, super pleased that the timing belt went smoothly, I did spend a lot of time doing the service especially since it was raining that day and the engine and front part of the frame were in the garage without a body in the way, spent about 30 minutes cleaning out mud behind the timing cover.

Here are the rear cab mounts I cut off the frame, each mount is drilled and bolted to the frame with 8 bolts

My new 2 ton engine crane putting in work, installing my 460,000km drivetrain into its new home, engine, trans, and tcase all connected

Drivetrain installed

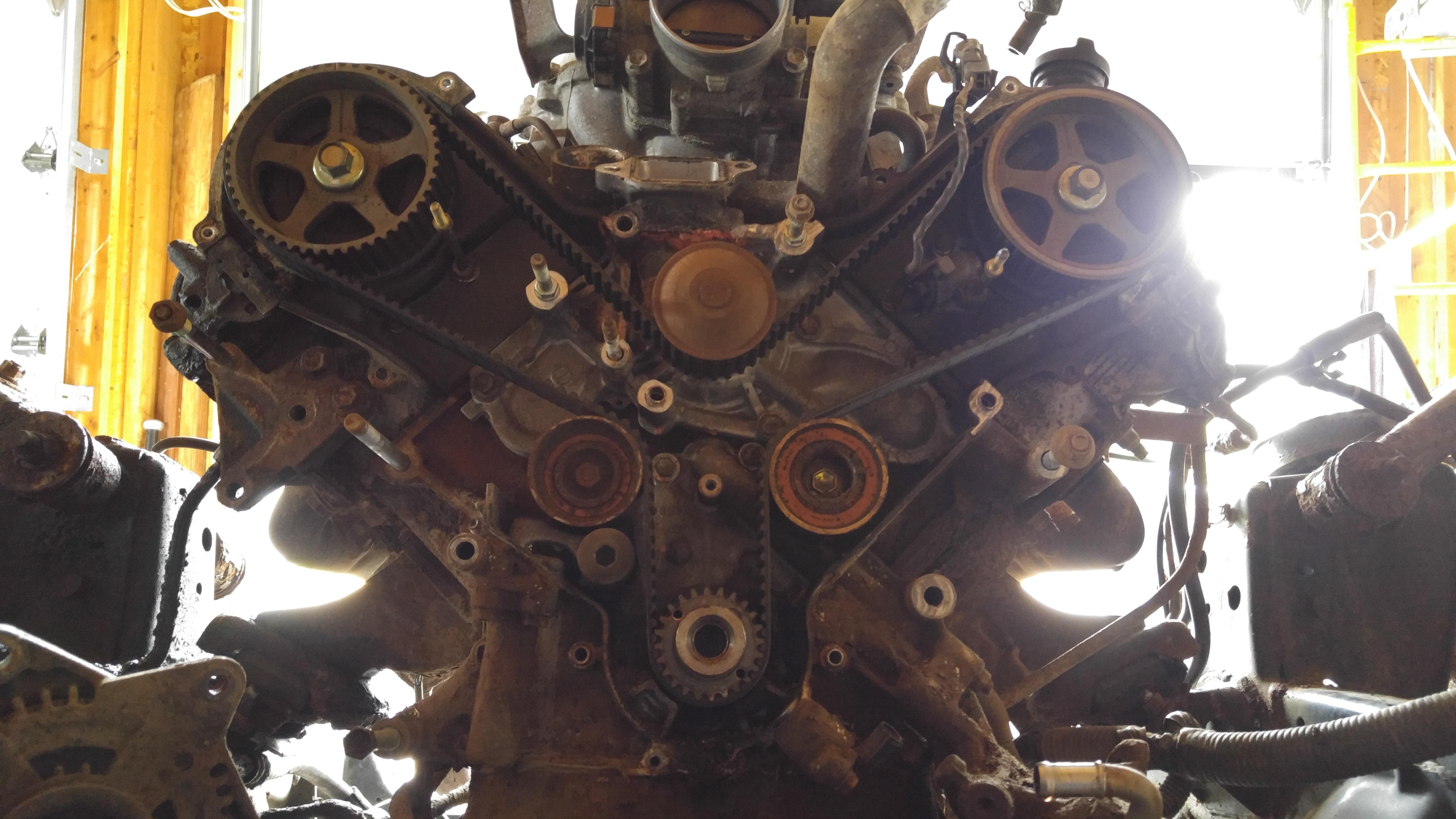

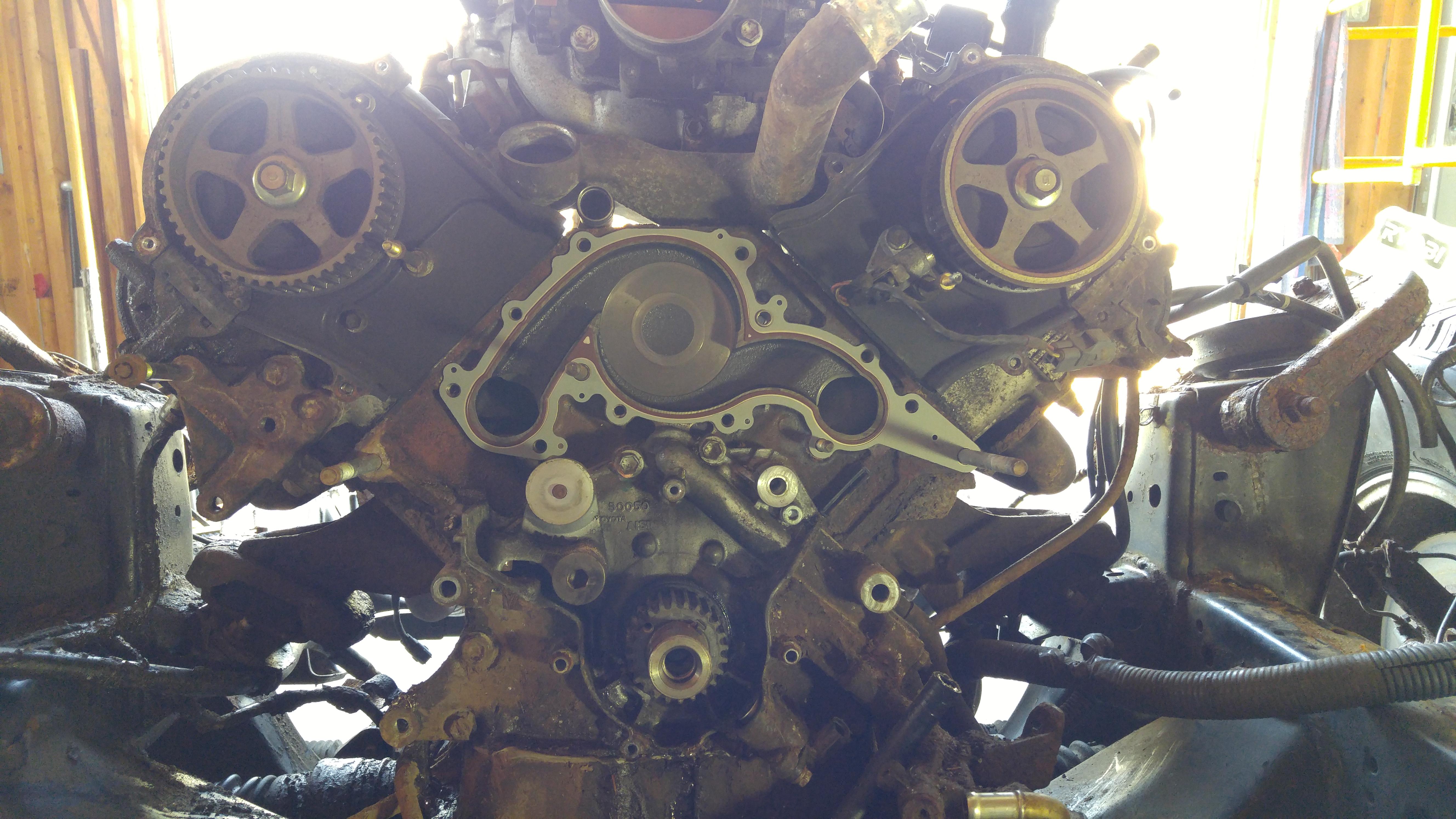

After the drivetrain was installed I maneuvered the front end into the garage for the timing belt and water pump

Water pump surfaces cleaned and new gasket installed

Figured out the easiest way to get the chassis and drivetrain under the cab, remove front struts, remove rear axle and leaf springs and use a farm jack to jack everything into place, then use the engine crane, lift the rear of the frame underneath the cab and reinstall the axle, then drop the cab onto the chassis

Here it is as it sits, tomorrow I’ll be finishing up the brake lines, swapping in the lower ball joints from the 03 as the 02 tundra lower ball joints use a smaller tie rod and won’t work with my pretty much brand new toyota outer tie rods for 03 and newer models, mounting the bed and painting my front bumper

And the most important upgrade, the captains chairs from the 02 and center console

forestmanParticipant

forestmanParticipantI’m back at it, got a full 6 hours in yesterday. Engine harness disconnected, doors removed, body mounts unbolted, front seats out. Just have a few more things to disconnect.

Checked the fitment of my winch into the bumper and what do you know the engage switch sticks up too far, took it out, bent it, filed it and now there’s plenty of clearance. No idea where I’m mounting the winch control box yet.

My 100 series Ebay snorkel showed up a few weeks ago but that’s furthest down the to-do list

Tomorrow I’m hoping I can have the body, drivetrain removed and clean the entire chassis and have it ready for the swap Monday.

A couple more trips to the parts store and then Monday the white truck’s being disassembled for the swap.

My plan for Monday is body off, drivetrain out, drivetrain in, timing belt, skid plates, body on(ish). I want to have the drivetrain swapped into the new chassis and then rolled partially into the garage for the timing belt/water pump service and remounting my skidplates better which will be super easy without a body in the way, during this time the single cab body will still be on blocks ready for the whole circus to roll back under its new home.

Then I have to swap the steering rack, spindles, ps pump, cv axles, rear axle housing, swap in the third that has a working lsd, install the snorkel, spark plugs, clean the throttle body, oil change, swap the coilovers, paint the bumper, mount the winch and bumper, extend the breathers optimally, and more probably.

Looking at the weather looks like I have until Thursday to get this all done

forestmanParticipant

forestmanParticipantIt shouldn’t be that hard, jack up the body, support it, roll the old pos rusted frame out, roll the new one in. Remember, I have 2 full rolling chassis and 2 sets of 31s and a set of 33s so I can play around with the wheels to make it a little easier. Lift the body with the 33s at 40 psi and then put on the 31s at 15 psi for a little extra room. I’ll be picking up a 2 ton engine crane at harbor freight on my way to pick up parts at CBI to swap the drivetrain in and out.

Good thing I’m only a month out from the swap, my rear cross member has cracked so there would be no wheeling, towing or hauling firewood this year.

forestmanParticipant

forestmanParticipantDream Truck Eh!

Here it goes

This is one of my dream builds where money and emissions are non-issues, the main purpose would be long distance travel, literally traveling all around the world and exploring areas that aren’t even on maps (I know everyone says that but I’m being serious, lol).

First, Buy a brand new Hilux Single Cab Chassis 2.8 diesel with Auto 6 speed trans in white

Now the fun begins

Get rid of the ifs, custom fab a 3 inch stretch 3 link making the wheelbase 124 inches, using a tru hi-9 center and fzj80 outers, arb locker and cro-moly shafts.

Then get a custom rear axle housing fabricated for a tundra 10.5 inch center with arb locker, full float conversion with drive flanges and 36 spline cro-moly shafts

Keep to rear leaf sprung to allow the installation of long range tanks (Hilux’s are SOA from the factory vs 70 Series Cruisers which =more clearance)

Get a custom fully enclosed canopy made with full size side doors, fridge , power center, inverter… all that good stuff.

Simple engine upgrades, unichip, snorkel, exhaust, tune

Trans shift kit, roll control for rear digs, lights, front and back winches

37 inch mud terrains, dual rear swing out tire carrier

There it is, my dream build, very simple

forestmanParticipant

forestmanParticipantSo after fiddling with a seized passenger side caliper twice, I gave up and made the trip to my grandparents where my parts truck is located.

Stole the caliper and rotor off the parts truck and got it fixed and checked the driver side as well. Inspected and brake cleaned the rear brakes which I had done last fall, everything was perfect.

I then realized how well matched my new to me topper is to the passenger side er.. patina

Since I got everything fixed in a couple of hours, I thought I’d get a head start on my frame/drivetrain/body swap.

So essentially I’m swapping my body and drivetrain into the new frame.

I parked the two trucks side by side and figured out the 6 bed mounts from the rear to the front are the same and the forward most bed mounts 2 rivets can be cut and directly bolted into existing holes in the access cab frame. The front body mounts and the mounts underneath the footwell are the same. The only mount that’s different is the rearmost body mount on the regular cab which can easily be cut flush with the frame and attached with 3/16 or 1/4 brackets.

I was thinking about just swapping the body but there are a few differences between 02 and 03 tundras, mainly transmission control and throttle body. The 02 has a weird combination cable/electronic throttle body, normal driving the electronic throttle body is used, and when you go maybe 70 to 100% throttle the throttle cable overrides the electronic throttle body to give you 100% throttle( which is more like 65%).

The 02 trans uses a kickdown cable for the trans vs full electronic control, also considering the guy that sold the truck to me said “this thing does wicked burnouts” I’m a little skeptical of its lifespan.

It could be done, pretty easily I guess by swapping ecu’s but my engine/trans, even at 455000km runs like a dream, oil pressure is perfect, doesn’t burn oil and my trans has the trick shift kit. So I’ll be running the same drivetrain at least for the next couple years, maybe I’ll disassemble the o2 engine and put it back together with some trick parts and install it at some point. either way I have a spare drivetrain ready to go if I need it.

So I started the disassembly of the engine bay, took the rad out, intake, ac components, everything to be able to lift the body off the frame, only thing left is the engine harness, fuel line, snip a couple brake lines, doors/seats, body mounts and that’s it.

I then realized why the temp gauge on these trucks doesn’t budge

Hopefully resume the swap end of April.

forestmanParticipant

forestmanParticipantI’ve been debating 4.56 vs 4.88 for a long time. Doing every calculation possible from 1st-OD at different speeds, and comparing to stock 4.56 makes more sense. 35s are my max, I might go down to a 34 or back down to a 33. I prefer running smaller tires (245 or 265s) in the winter as well.

The ratios in the A340F trans are 2.804, 1.531, 1, and 0.705.

Stock gears are 3.909 with 265/70/16 (30.6), rpm at 100km/h = 1891 , at 120km/h = 2270

3rd gear at 120km/h 3219 rpm

4.56 gears 4.555 with 315/75/16 (34.6), rpm at 100km/h = 1949 , at 120 km/h = 2339

3rd gear at 120 km/h 3318 rpm

So even with 315s I’ll be slightly over geared

If I run 34s at 100km/h = 2019 rpm

4.88s are just too low in my opinion. If I was v6 4.88 100%, but with the shift kit/valve body mods I can climb hills at 85 km/h with 33s and stock gears at 1500rpm. Shift kit really changes the way your transmission responds, torque converter stays locked up longer, quicker firmer shifts, awesome downshifts, higher line pressure, just makes everything better and better fuel economy.

I also like the extra tooth on the pinion, 9 vs 8, so my mind is made up 4.56.

forestmanParticipant

forestmanParticipantThe donor vehicle all cleaned up

The bumper I decided not to install until the frame swap is complete

The OME coilovers are really nice, definitely ride harsher at slower speeds than the bilsteins when new but at higher speeds on rough roads and hard hits they are a dream.

The stance after installing the ome coilovers last fall

Since I didn’t install the winch bumper I rigged up the chrome one for better aesthetics, haha

Glad to be back!

-

This reply was modified 7 years, 11 months ago by

forestman.

forestman.

forestmanParticipant

forestmanParticipantHey guys, Noey directed me to the new site. I kept the same name and same vehicle, apart from 5 new shiny… err matte things

-

This reply was modified 7 years, 11 months ago by

-

AuthorPosts